developing a modelling strategy of the most-onerous VCEs with hydrocode software

A major UK petrochemical facility commissioned D J Goode to design a blast resistant structure adjacent to their control room, providing additional facilities as well as acting as a launch point for any rebuilding efforts after a significant event.

The facility processes natural gas at high temperature and pressure. These operating conditions, as well as the large volume flow rate through the facility, produce several potential accident scenarios including jet-fires and vapour cloud explosions (VCEs) – the most severe and recent of which in the UK was the fire, and resulting explosion, at Buncefield Oil Terminal in 2005 [Figure 1].

An ideal solution to model the VCE would be to use a high-level two-phase computational fluid dynamics (CFD) model, where the turbulence of the natural gas leakage could be modelled to determine the volume of vapour that is contributing to the creation of the blast overpressure. It has been demonstrated in models of historical events that the turbulent mixing of the two gas streams is vital to accurately find the proportion of the vapour cloud that is highly congested and within the flammability limits.

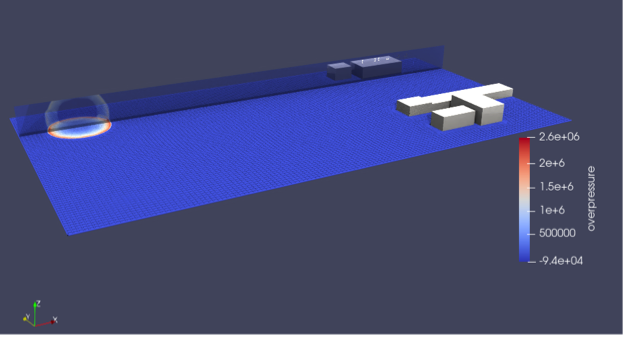

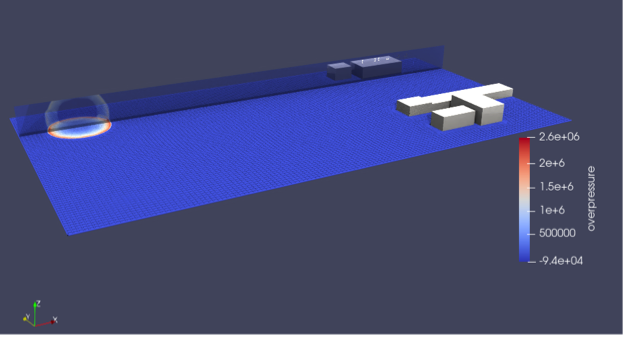

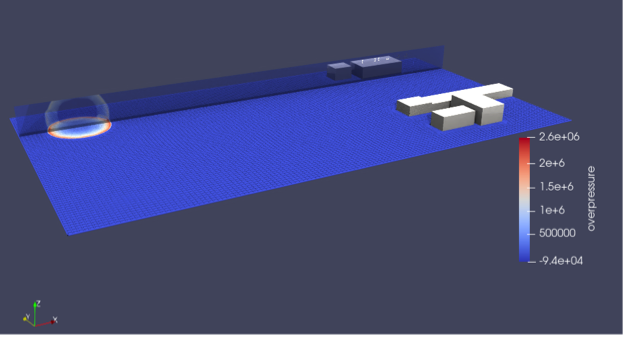

D J Goode have developed a modelling strategy of the most-onerous VCEs with the hydrocode software, Blastfoam [1], using an equivalent TNT mass to the determined petrochemical event [Figure 2]. The equivalent TNT method has been validated using historic safeguarding reports from the facility, as well as two empirical methods – Multi-Energy and Baker-Strehlow-Tang which utilise combustion-energy scaled distances and overpressure ratios. This derivation route would have a significantly reduced computational demand and overall run-time, and therefore provide increased flexibility, which is vital to a project as it undergoes the initial RIBA stages.

The two empirical methods used follow assumptions that the vapour cloud is at stoichiometric conditions and therefore an explosive efficiency is required to account for the turbulent mixing. Efficiencies determined in the analyses matched well with the suggested in literature for highly congested and confined volumes.

A comparison of the hydrocode and empirically derived methods found that the numerical calculations produced a high level of accuracy within the regions of interest. Therefore, the proposed method would be suitable to calculate member sizes, glazing make-ups and response of cladding systems.

Please CONTACT US if you would like more information.

[1] Synthetik Applied Technologies, ‘Blastfoam’, hydrocode software

Accessible from: https://www.blastfoam.org/

Figure 1 Buncefield post-VCE (2005), photographed by Chiltern Air Support Unit

Figure 2 Simplified hydrocode model of VCE

Jack M. GRADUATE ENGINEER

Share this page